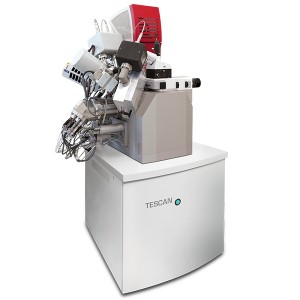

FERA – Xe Plasma Source FIB/SEM

Overview

Tescan’s FERA is the world’s first fully integrated Xe Plasma source FIB with SEM. This unique combination allows the user to utilise extremely high ion currents, up to 2µA, which increases sputtering rates to over 50 times those possible with conventional Ga source FIBs. This means that the FERA is able to mill large amounts of material that would have been impossible on other systems due to time restraints.

The FIB-SEM meets the current needs of both research and industry, providing excellent resolution at high beam current. Powerful, user-friendly software make the FERA an invaluable analytical tool.

Other advantages of the FERA Xe-Plasma FIB that that users will benefit from that are the result of combining an SEM with a FIB and the latest high-performance electronics include:

- Faster image acquisition

- Ultra-fast scanning with compensation for static and dynamic image aberrations

- Built in scripting for user defined applications

Modern Optics

The Tescan FERA incorporates the latest in modern optics. User benefits include:

- A unique Wide Field Optics design with a proprietary Intermediate Lens (IML) offering a variety of working and displaying modes, e.g. with enhanced field of view or depth of focus, etc.

- Real time In-Flight Beam Tracing for the performance and beam optimisation integrating the well-established software Electron Optical Design. It includes also direct and continual control of beam and beam current.

- Fully automated electron optics set-up and alignment

- Fast imaging rate

- Unique live stereoscopic imaging using advanced 3D Beam

- Technology that opens up the micro and nano-world for an amazing 3D experience and 3D navigation

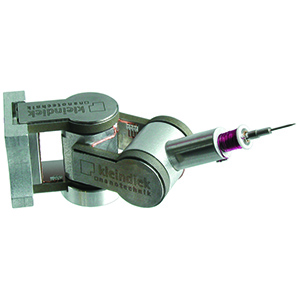

High Performance ION Optics

The FERA FIB-SEM utilises a sophisticated high performance plasma i-FIB system. This means the user can enjoy both extremely fast and precise cross sectioning and material removal.

Easy Maintenance

The FERA Xe-Plasma FIB has been designed to maximise the performance of the instrument and reduce downtime. Keeping the FIB-SEM in optimal working order has been made easy through thoughtful engineering which have been designed to make maintenance tasks as simple as possible.

Automated Procedures

Many operations of the microscope have been automated to reduce operator effort. Things like instrument set up, adjustment of working distance, brightness, manipulator navigation and sample analysis etc. only require the press of a button.

The user can also automate many other functions like stage control, image acquisition and sample analysis using the built-in scripting language which further decreases the amount of user intervention required.

User-Friendly Software Tools

Tescan SEMs employ a user-friendly software interface allowing:

- Multiple user levels, multiple user accounts, multi-user environment that are translated into many languages.

- Easy to use control of all SEM parameters, simultaneous FIB/SEM imaging

- Live imaging with multiple window support, highly customisable live image parameters

- Image management using Image Manager, report creation, on-line and off-line image processing

- Project management using Project Manager

- Embedded automated diagnostics (self-test)

- TCP/IP remote control, network operations and remote access/diagnostics

- Free SW bug fixes and updates

Chamber Types

| Chamber type | XM | GM |

| Internal dimensions | 285 mm (wide) x 340 mm (deep) | 340 mm (wide) x 315 mm (deep) |

| Door | 285 mm (wide) x 320 mm high | 340 mm (wide) x 320 mm (high) |

| Number of Ports | 12+ | 20+ |

| Chamber suspension | Pneumatic | Active vibration isolation (integrated) |

| Specimen stage | Fully-motorised | Fully-motorised |

| Type | Compucentric | Compucentric |

| Movements | X = 130mm Y = 130mm Z = 100mm Rotation: 360° cont. | X = 130mm Y = 130mm Z = 100mm Rotation: 360° cont. |