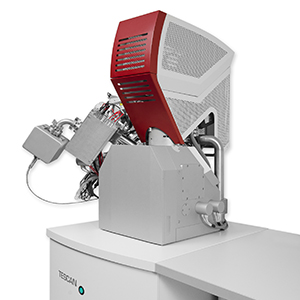

PicoMill TEM Specimen Preparation System – Ion Mill for Post FIB TEM Specimen Preparation

Prepare the highest quality electron transparent TEM specimens

FIBs are a commonly employed instrument for preparing TEM specimens to determine structure at the atomic level. However, these specimens can often become modified by amorphisation or gallium ion implantation when prepared using a high energy FIB.

The PicoMill system is the ultimate companion for your FIB to optimise TEM specimen preparation quality. Use your FIB for rapid milling and follow this with low energy polishing using the PicoMill system to remove any amorphous/implanted layer or other artefacts. This is the best way to ensure that you are analysing unmodified materials.

The PicoMill system combines an ultra-low energy, inert gas ion source, and a scanning electron column with multiple detectors to yield optimal TEM specimens.

Let your FIB do what FIBs do best

Let PicoMill do the rest!

Key Benefits

- Achieve ultimate specimen quality free from amorphous and implanted layers

- Complements FIB technology

- Milling without introduction of artefacts

- Advanced detector technology for imaging and precise endpoint detection

- In situ imaging with ions and electrons

- Microscope connectivity for risk-free specimen handling

- Fast, reliable, and easy to use

Ion Optics

Ion source comprising a filament-based ionisation chamber and electrostatic lenses

Ion source comprising a filament-based ionisation chamber and electrostatic lenses- Ultra-low ion energies inert gas (argon) source (50 eV to 2 kV)

- Sub-micron beam diameter

In situ imaging

In situ imaging of the specimen before, during, and after ion milling allows you to carefully monitor the process at all stages. The PicoMill includes:

- A backscatter electron detector (BSE) for in situ imaging with electrons

- A secondary electron detector (SED) for in situ imaging with ions and electrons

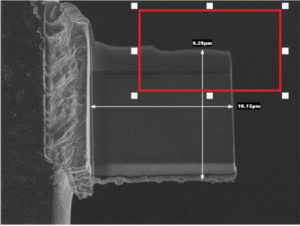

- A scanning/transmission electron detector (STEM) for electron transparency and endpoint detection

specimen Handling

Microscope connectivity reduces specimen handling

Microscope connectivity reduces specimen handling- Uses your TEM holder to minimise specimen handling

- TEM-style holder allowing positive and negative tilt

- Precise milling angle adjustment

- The ion beam impingement angle is programmable from -15 to +90°.

- Milling specimens at a low angle of incidence (less than 10°) minimizes damage and specimen heating

Software Controls

- Total control of all milling/polishing parameters

- Storage of recipes for rapid recall

- End-point detection/process termination using a STEM detector to detect the transmitted electrons