Automated Particle Detection and Analysis for Protein Formulations – Hound

Automatically identify unwanted particles and contaminants in your drug batch

Overview

The Hound is the ultimate tool to detect unwanted particles that can potentially contaminate the quality of your drug production run. It can automatically locate, identify and characterise the offending particles within minutes using a combination of:

- Microscopy

- Raman spectroscopy

- LIBS Laser Induced Breakdown Spectroscopy

What Can Hound Measure

Hound can determine the following:

- Chemical composition

- Elemental composition

- Particle count

- Particle shape

- Particle size

- Particle colour

Simple Operation

Step 1

Simply pour your suspicious sample through a filter round or pipette onto a wet round and drop it into your Hound. The gold-coated surfaces catch everything and eliminate the background noise.

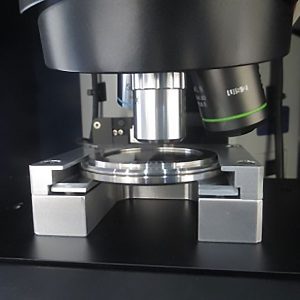

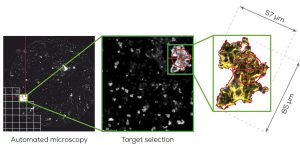

Step 2 – Microscopy

With all the particles trapped on the gold surfaces, Hounds microscope automatically images everything including translucent proteins using bright-field, dark field and fluorescence imaging. Using automated image analysis, Hound scans the entire sample identifying the size and shape of every particle, allowing you to easily detect unwanted particles.

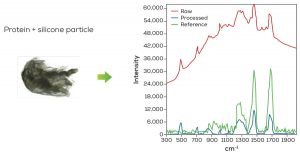

Step 3 – Raman Spectroscopy

Raman spectroscopy identifies all proteins and organic materials by comparing their chemical composition to a customisable database of reference materials. You will know straight away if any particle is a protein or contaminant.

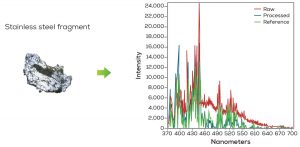

Step 4 – LIBS

If other particles are detected such as metallic particle from a fermenter or glass particle vial, Hound is able to determine their composition using LIBS (Laser Induced Breakdown Spectroscopy). By shooting the particle with a laser, a tiny amount of materials is ionised into a plasma which is measured with a spectrometer and analysed against a database and identified.

Specifications

| Description | Specification |

|---|---|

| Microscope | Imaging: 2 MP color camera, 5x, 10x, 20x (DF and BF), 50x objectives Illumination: Integrated bright-field and dark-field illumination Particle size range: 0.5 μm – 15 mm Accuracy: ±5% sizing (magnification dependent), ±15% counting |

| Raman | Laser: Adjustable power, 50x, 0.55 NA, 5.0 mm WD 785 nm: ≤50 mW, 200–2000 cm-1, resolution 5 cm-1 532 nm: ≤20 mW, 200–3200 cm-1, resolution 5 cm-1 Minimum particle size: 0.5 μm Database: 250 typical contaminants, expandable |

| LIBS | Laser: Safety Class 1, Pulse-LASER w/130 μJ, 3 ns duration, 20 x UV lens Spectral range: 350–700 nm, resolution 1 nm Minimum particle size: 3 μm Database: 50 typical contaminants, expandable |

| Filter Rounds | Material: Gold coated polycarbonate (PC) — 0.5 μm min. particle size Gold coated polytetrafluorethylene (PTFE) — 2 μm min. particle size pH range: 1–14 |

| Wet Rounds | Material: Gold or nickel coated Optical transmission: 255–850 nm |

| Software | 21 CFR Part 11 & USP <788>, Method 2, ISO 8871-3:2004 compliance included |

| Environment | Temperature range: 15–30 °C Humidity: 0–95% relative humidity (non-condensing) |

| Physical properties | Weight: 30 kg Dimensions: 60 cm W x 60 cm D x 80 cm H Recommended bench space: 180 cm W x 80 cm D x 110 cm H |

| Electrical | 230V/500W |