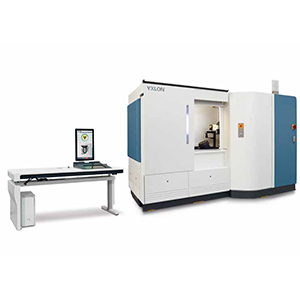

FF Series High Resolution Computed Tomography Inspection Systems (CT) – FF20 and FF35

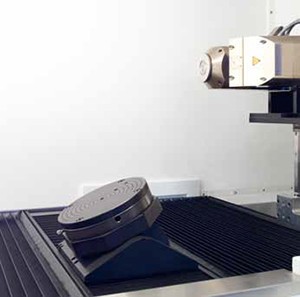

The FF Series Computed Tomography inspection systems (CT) models FF20 and FF35 exploit YXLONs Extensive expertise in x-ray and CT testing. They are suited to the inspection of very small to medium sized components. These solutions have been designed to seamlessly blend into your workflow with their fast and intuitive operation coupled with high uptime.

Design Features

FF Series CT machines combine a host of intelligent and user-friendly features to create an instrument that is simple-to-use and generates useful data quickly to you can make adjustments to your process as quickly as possible to minimise downtime.

Key Features

Key features include:

- Intuitive touchscreen Geminy user interface that enables easy combination of 2D and 3D inspections in one sequence

- Intelligent automation

- Revolutionary icon-based system for creating inspection sequences using drag and drop icons

- Many automated functions help improve your efficiency

- Automated collision protection for worry-free sample manipulation

- Remote system monitoring with push messaging

- Flexible Region of Interest (ROI) thanks to off-centre virtual rotation axes

- Expanded inspection envelope with horizontal field of view extension

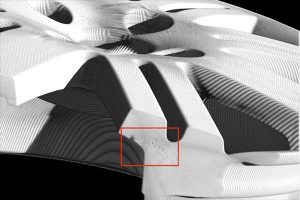

Ensuring High Image Quality

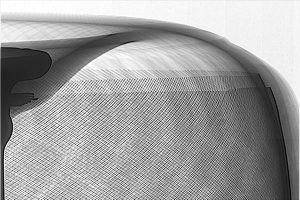

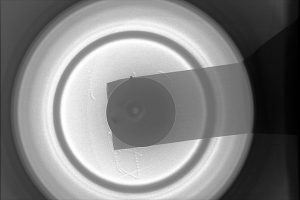

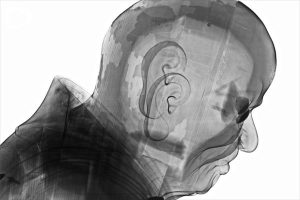

The FF Series instruments allow you to combine a high power reflection tube and a nanofocus transmission tube during a single inspection sequence. The YXLON real ROI scan that allows off-centre virtual axis scanning enables you the ultimate in flexibility with regards to materials and component sizes.

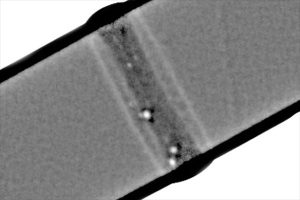

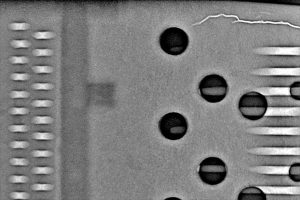

Helical CT scanning also allows you automatically compose a single accurate image eliminating the need for stitching of different areas. Furthermore, supreme image quality is guaranteed by ring artefact and beam hardening correction.

|  |

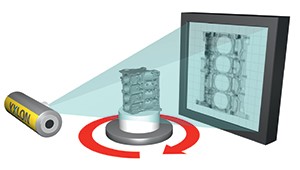

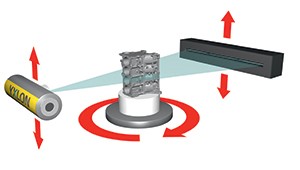

| Principle of cone beam CT - The model comprises almost all information acquired by the detector during the rotation. | Principle of Helical CT - With step-wise rotation of the sample and step-wise vertical manipulation of the x-ray tube and flat panel detector all information for precise 3D volumes of long parts can be obtained. |

Other features that contribute the excellent image quality include:

- Water-cooled x-ray tube with 600nm small focal spot size

- Motorised focus-detector distance

- Multiple gain detector correction

- Step-wedge calibration

- High quality components e.g. premium angle encoder and linear encoders

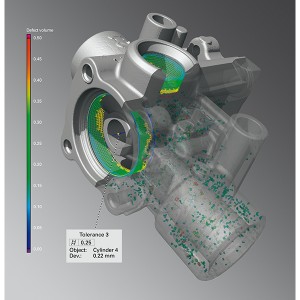

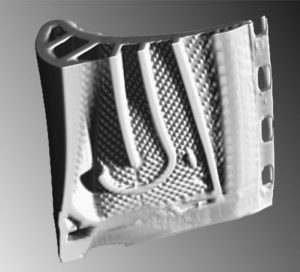

Applications

The FF series CT inspection systems have been designed with the exacting needs of the automotive, electronics, aviation and materials science industries in mind. They typically find application in:

- Research and Development (R&D)

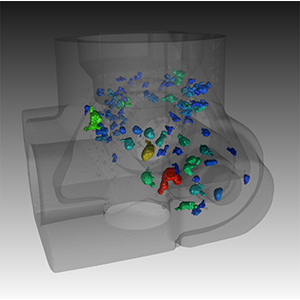

- Failure analysis

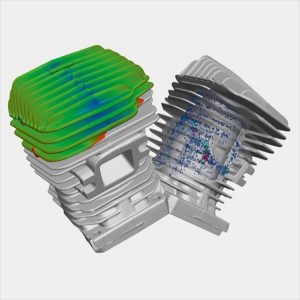

- Process control

- Small series inspection

- Combined DR-CT inspection

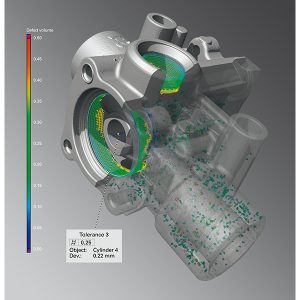

- CT metrology

- Defect analysis

- Materials analysis

- Assembly checks

- Quality control

- Checking dimensional accuracy and tolerances

YXLON FF Series CT Systems

| FF20 CT | FF35 CT Single Tube | FF35 CT Double Tube | |

|---|---|---|---|

|  |  |

|

| Part Size | ++ | +++ | +++ |

| Materials Density | ++ | +++ | +++ |

| Part Weight | + | ++/+++* | ++/+++* |

| Detail Visibility | +++ | ++ | +++ |

| Combined 2D and 3D | ✔ | ✔ | ✔ |

| Helical CT | ✔ | ✔ | ✔ |

| Real ROI (Virtual Rotation Axis) | ✔ | ✔ | ✔ |

| Powered by YXLON Geminy | ✔ | ✔ | ✔ |

| Brochure | Download | Download | Download |