In Situ TEM Heating Platform Wildfire

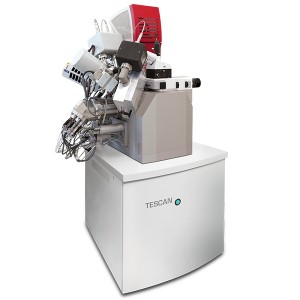

The Wildfire from DENSsolutions allows you to perform in situ experiments in your TEM with the ability to vary the temperature. This enables you to perform live and dynamic studies live inside your TEM with no need to remove the sample. This simple system transforms your TEM from a static imaging tool into a multi-functional laboratory speeding up your research.

The in situ Advantage

Using the Wildfire platform you can perform studies under conditions that replicate real world environmental service conditions. The ability to carry out dynamic studies gives you the power to pinpoint exactly when an event such as transformation takes place. This in turn empowers you to be able to modify your material, adjust your process or further optimise conditions to suite your intended application.

Key Features

- Observe dynamic structural changes in real-time

- Extremely fast response times (heating rate up to 200°C/ms) ensures you dont miss a thing

- Unrivalled stability (down to 6pm/sec at 800°C)

- In situ heating reduces the chance of sample contamination resulting in improved image quality

- Robust localised closed loop heating system with feedback allows maximum control

- Compatible with EDX for chemical mapping

Plug and Play Solution

Wildfire, as well as other DENSsolutions TEM platforms comes as plug and play system and are manufactured to suit your existing TEM. The system comprises:

Wildfire, as well as other DENSsolutions TEM platforms comes as plug and play system and are manufactured to suit your existing TEM. The system comprises:

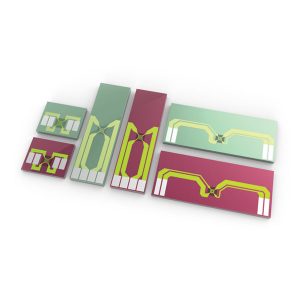

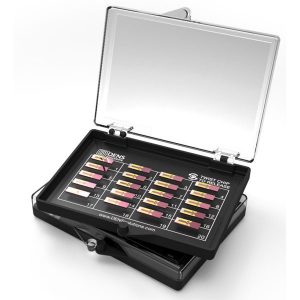

- Nano-chips

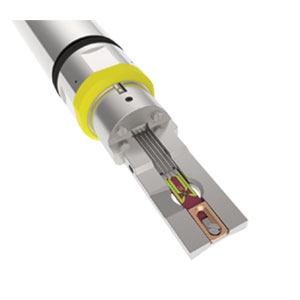

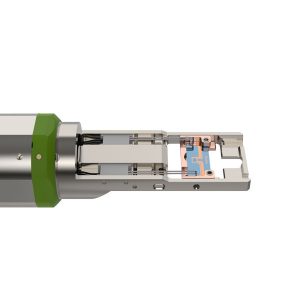

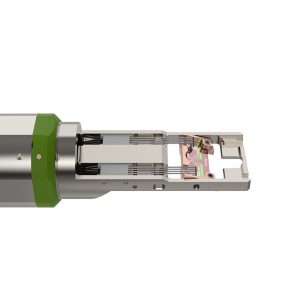

- Wildfire sample holder

- Holder stand

- Laptop with Digiheater software

- Control box

Nano-Chip Technology

Nano-Chips are state-of-the-Art functional sample carriers that offer a replacement for conventional copper TEM grids. Each Nano-Chip creates a micro-scale laboratory environment within the confines of your existing TEM.

Using MEMS (micro-electro-mechanical systems) technology they allow you expand the capability of your TEM by enabling you to control the local environment and stimuli that your sample is subjected to.

The low thermal mass and minute power consumption provides extremely rapid response times in combination with highly reliable performance.

Key Features of Wildfire Nano-Chips

- Fabricated to produce optimal stability as well as a chemically inert and electrically insulated environment

- Localised heating to the same scale as your sample ensures the highest levels of control, homogeneous temperature and maximum temperature reliability

- User-friendly software allows custom profiling, real-time temperature output and complete data logging

- Localised closed-loop temperature feedback provides the ultimate in sample stability, temperature response time and accuracy

- >90 hours at elevated temperatures with no effect on TEM performance

- Nano-chips support film options to suit all applications

System Specifications

| FEI Compatible | JEOL Compatible | ||||

|---|---|---|---|---|---|

| Wildfire S3 | Wildfire S5 | Wildfire D6 | Wildfire S3 | Wildfire D6 | |

|  |  |  |  |

|

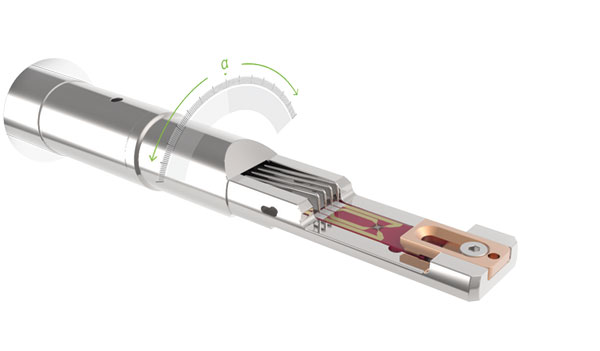

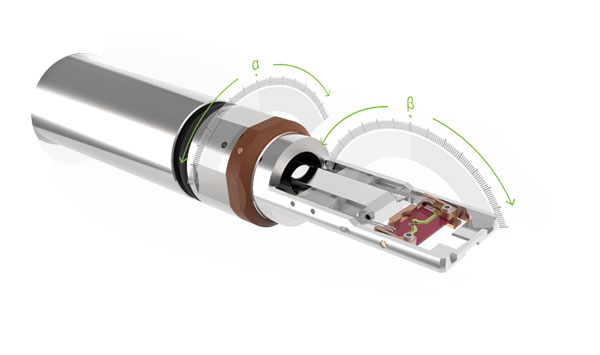

| Tilt control | from microscope | from additional beta control device | |||

| Alpha (α) tilt | ±30° | ±70° | ±25° | HRP ± 20° | HRP ± 20° URP ± 15° |

| Beta (β) tilt | na | na | ±25° | na | HRP ± 15° URP ± 15° |

| Compatibility (PP) | ST, XT, T, BioT | UT, ST, XT, T, BioT | ST, XT, T, BioT | HRP, HTP, CRP, HCP | UHP, HRP, HTP, CRP, HCP |

| (HR)TEM | Yes | ||||

| ETEM | Yes | ||||

| Tomography | Yes | Optimised | Yes | ||

| EFTEM | Yes | ||||

| (HR)STEM + EELS/EDX | Yes | ||||

| Request a quote | |||||

| Brochure | Click here to download the DENSsolutions Widfire in situ TEM Heating Platform brochure. | ||||

Single and Double Tilt Solutions

Nano-Chip Specifications

| Control method | 4 point resistive feedback |

| Temperature range (guaranteed) | Room temp. to 1300°C |

| Max. temperature | 1500°C |

| Temperature accuracy | <5°C |

| Temperature stability | <1°C @ 1300°C |

| Heating rate | 200°C/millisecond |

| Quench rate | 200°C/millisecond |

| Settling time | <2 seconds |

| Ultimate sample drift | 0.5nm/minute |

| Resolution | <0.6Å |

Wildfire suits a wide range of application. Provided below is a brief list of some potential applications.

- Catalyst and chemical reactions

- Phase transformations

- Melting and recrystallization

- Diffusion and sintering

- Grain growth

- Interface and surface studies

- Heat treatment and precipitation

Introduction to the Wildfire S3 In Situ TEM Heating Platform

Loading the Nano-Chip from the Wildfire TEM Heating Platform

Unloading the Nano-Chip from the Wildfire TEM Heating Platform

The Wildfire In Situ TEM Heating Platform for FEI TEMs

Similar Products

Climate

In Situ Gas/Temperature TEM Platform

Lightning

In Situ Bias/Heating TEM Platform

Ocean

In Situ Liquid Cell TEM Platform