Smart Sample Loading System (SSLS) for Primus WDXRF Spectrometers

Rigakus Smart Sample Loading System (SSLS) for ZSX Primus wavelength dispersive x-ray fluorescence (WDXRF) spectrometers increases the flexibility of the instrument and enhances its productivity. It is the perfect solution for operations with large numbers of samples to process and/or requirements for rapid results.

For samples that are suitable, a vacuum chuck automatically picks the samples up and loads them into pre-loaded sample holders. This has two distinct advantages:

- Time is saved as the operator no longer needs to manually load sample into sample cups

- The sample deck can cater for more samples than before, enabling the operator to load the instrument with more work

Suitable Samples

The SSLS is ideally suited to samples with non-porous upper surfaces that the vacuum chuck can attach to. Fusion beads and metal discs are prime candidates. Pressed powders and metal and plastic pressed powder holders are also suitable.

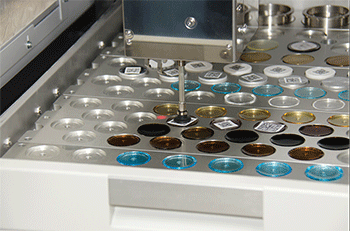

Maximum sample weight is 50g, while racks are available to cater for samples 32 and 40mm in diameter, although other sizes can also be dealt with. Racks can also be chosen to suit the various sample sizes, i.e. it is possible to combine the measurement of 35 and 40mm samples at the same time.

Sample Handling

A robotically controlled vacuum chuck rapidly and reproducibly picks up samples from the racks and locates them in to the measurement sample holder. The measurement sample holder has specific sized rings to ensure each measurement conditions are optimised for all sample sizes.

Sample Tracking

2-dimensional bar codes are affixed to the non-measurement side of each sample making sample tracking a cinch. Prior to the sample being loaded into the pre-evacuation chamber, a scanner reads the code and loads the sample details into the control software.

Applications

The Smart Sample Loading System is suited to operations that have a high sample throughput rates such as:

- Industrial minerals

- Cement

- Metals

- Mining

Key Features

- Increases the number of samples held on deck e.g. maximum loading increases from 48 to 104 for 35mm samples

- Different size sample trays can be combined to cater for combined analyses e.g. 35 and 40mm samples can be analysed at the same time using simple software configuration

- Automated analysis

- Optional barcode reader increases efficiency and reduces the chance of operator error

- Sample priority can be easily changed via the software interface without interrupting the measurement procedure