Silicone Coating Analysis for Injectable Devices – Bouncer

Many medical devices have a silicone coating. The thickness of this coating can dictate how the device will perform in service. Bouncer from Unchained Labs can quickly and easily tell you if you silicone coating is too thick, too thin, or just right.

In applications such as syringes, there is an optimal silicone coating thickness which can can dictate the performance of the device e.g.:

- Not enough silicone the plunger gets stuck

- Too much silicone free silicone can contaminate your biologic and cause the protein to aggregate

What Bouncer Measures

Bouncer is able to measure the following properties about your silicon coating:

- Coating thickness

- Coating distribution

- Coating mass

Silicone Coating Thickness Measurements

Bouncer is able to measure the thickness of your silicon coatings in just minutes. It can cope with a variety of sample types e.g. syringes, cartridges or vials. It is able to cope with all coatings regardless of how they applied.

Measuring your samples is easy. Just load it into the stage and Bouncer does the rest.

How Does Bouncer Measure Silicone Coating Thickness?

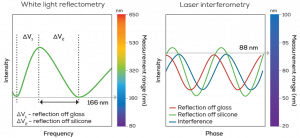

Bouncer uses basic white light interferometry for sprayed on coatings. In this mode it can measure coating thicknesses down to 80nm.

For coatings baked onto glass, Bouncer uses laser interferometry and can measure coatings down to 20nm thick.

In either mode, Bouncer can provide instant results on coating thickness.

Silicone Coating Distribution

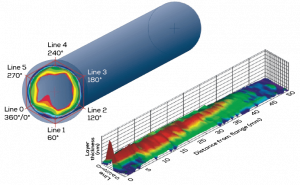

The consistency of the silicone coating is also very important to the performance of your device. As such Bouncer can measure the consistency of your coating by looking at the entire inside surface.

By analysing thousands of data points in 360°, Bouncer can provide both 2D and 3D analyses that let you know whether your coating that falls between optimal tolerances or not.

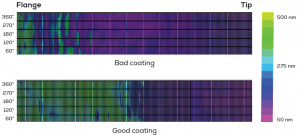

Quality Control

If you know what coating thickness will make your device perform as it is intended, Bouncer makes it easy to QC them. By providing thickness and distribution data, Bouncer can help you to decide which devices will and wont work, so you can reject any that dont meet the specification.

FDA Compliant

The Bouncer is FDA Regulation Title CFR 21 Part 11 compliant.

How Does Bouncer Measure Silicone Coating Thickness?

Bouncer uses basic white light interferometry for sprayed on coatings. In this mode it can measure coating thicknesses down to 80nm.

For coatings baked onto glass, Bouncer uses laser interferometry and can measure coatings down to 20nm thick.

In either mode, Bouncer can provide instant results on coating thickness.

Silicone Coating Distribution

The consistency of the silicone coating is also very important to the performance of your device. As such Bouncer can measure the consistency of your coating by looking at the entire inside surface.

By analysing thousands of data points in 360°, Bouncer can provide both 2D and 3D analyses that let you know whether your coating that falls between optimal tolerances or not.

Quality Control

If you know what coating thickness will make your device perform as it is intended, Bouncer makes it easy to QC them. By providing thickness and distribution data, Bouncer can help you to decide which devices will and wont work, so you can reject any that dont meet the specification.

FDA Compliant

The Bouncer is FDA Regulation Title CFR 21 Part 11 compliant.

Specifications

| Description | Specifications |

|---|---|

| Hardware | Camera: 1MP colour camera Illumination: Halogen Laser: Class 1 Lens: 10x + 20x |

| Software | 21 CFR Part 11 compliant |

| Syringe Types | Diameter: 6mm to 22mm diameter Length: Up to 90mm |

| Measurements | Resolution: 1-20 points/mm, 1-36 lines, max. 200 points/line White light reflectometry thickness accuracy: ±5% @150nm Laser interferometry thickness accuracy: ±10nm @50nm |

| Environmental | Temperature range: 16 - 25°C Humidity: 0 - 60% non-condensing |

| Physical | Weight: 50kg Dimensions: 60cm (W) x 60cm (D) x 80cm (H) Recommended bench space: 180cm (W) x 80cm (D) x 110cm (H) |

| Electrical | 220V, 500W |